Support for cable works for the construction of a new unit at Kozienice Power Plant

Scope of the project

Elsta Sp. z o.o. on behalf of the general contractor - MHPSE - it was tasked with making cable routes and laying cables on the construction site of a 1075 MW unit. It is currently the largest such project in Europe, with a value of over PLN 6.3 billion. The cable works were to be performed from December 2015 to July 2017. The project did not really start until April 2016, when the first work fronts were secured. In July 2017, the project is nearing completion - in December, the unit was put into operation.

Data:

- Over 720,000 man-hours have been worked

- Over 100 km of cable routes were built under difficult conditions

- More than 1,700 cable drums were used22,000 cable sections with a total length of more than 1,300 km have been laid and connected

- Final measurements were made for 95% of the cable sections laid

0

work hours

0

cables routers

0

cable sections

0

cables

Challenges and issues

- The project was dynamically changed in the course of implementation - almost 70 revisions within 18 months

- Expected accumulation of works due to the shortened implementation time

- The need to document changes to the billing of additional works and materials

- Twelve subcontracting companies, 20 installation brigades - 440 employees at the same time on the construction site

- A large number of cable drums stored in multiple locations on a vast construction site

- Difficult conditions of implementation, many possible collisions with other works on the construction site

Components

01

AMAGE Desktop

Management application for coordinators of cable works. All information via the synchronization server was sent and visualized in the main application

02

AMAGE CE/Fx

Applications dedicated to handheld devices and tablets adapted to harsh environmental conditions. They allowed for work reporting, support of verification and connection teams.

03

Oznakowanie

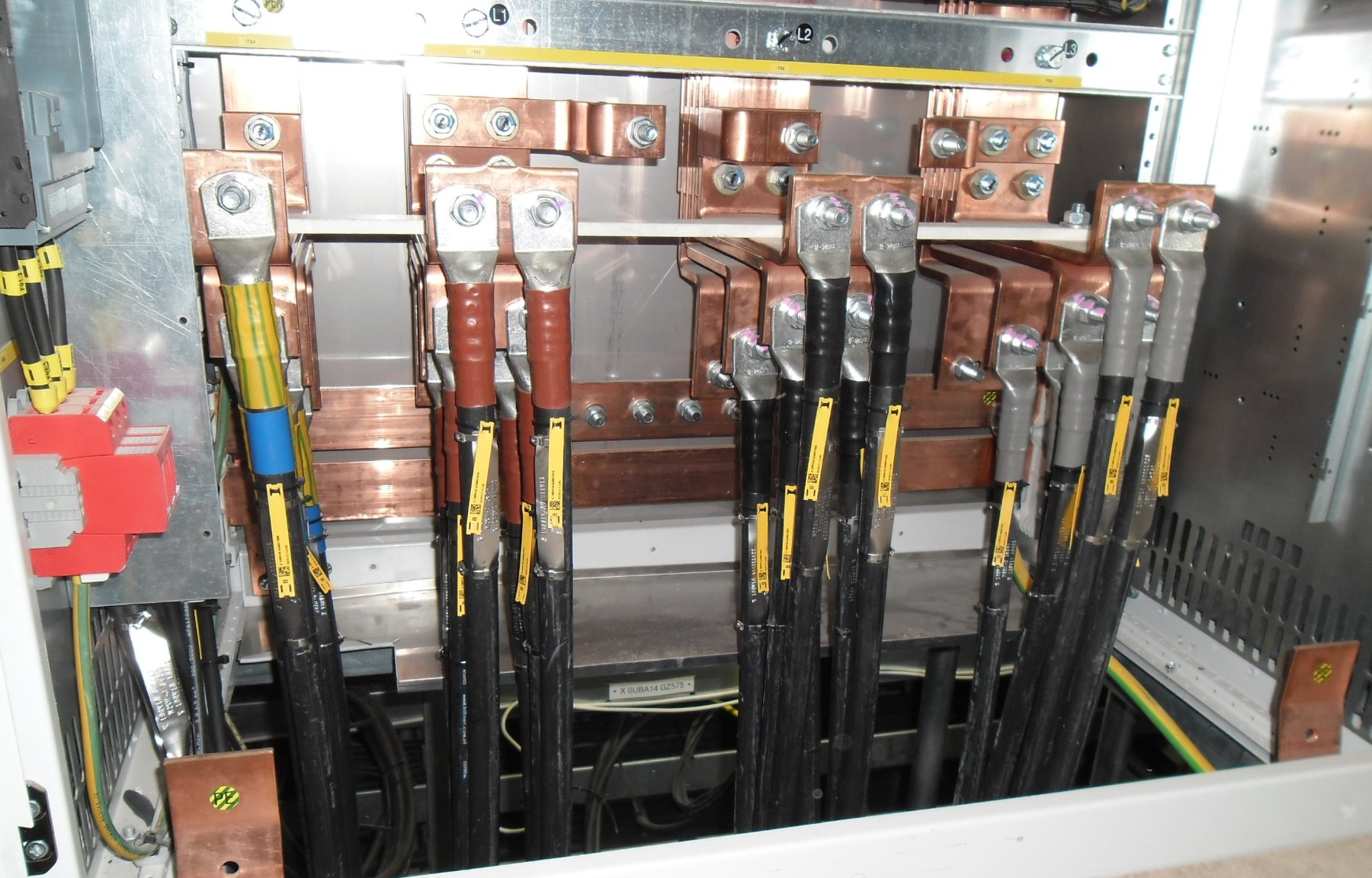

Labeling dedicated and designed for this project on labels intended for cable harnesses. They contained information necessary for the supervision process, but also technical information.

Solution

- Possibility to report faults of individual cables - service reports management

- Planning the work of own and subcontractors' installation teams - work orders

- Conducting checking and measurement works using mobile applications for a tablet

- Access to documentation via devicesmobile

- Generating unique 2D identifiers and printing cable labels

- Możliwość zgłaszania usterek poszczegónych kabli- zarządzanie zgłoszeniami serwisowymi.

- Planowanie pracy brygad instalacyjnych własnych i podwykonawców – zlecenia pracy

- Prowadzenie prac sprawdzających i pomiarów za pomocą aplikacji mobilnych na tablet

- Dostęp do dokumentacji poprzez urządzenia

mobilne - Generowanie unikalnych identyfikatorów 2D i druk etykiet kablowych

Opinion

We knew that without an IT tool we would not be able to control the piling work. However, we did not expect that thanks to the AIM system and cooperation with its supplier, it would be possible to both effectively maintain high efficiency of work when laying cables and significantly reduce the amount of losses related to their waste. At the same time, quality control was carried out on an ongoing basis and precise as-built documentation was prepared. Due to constant monitoring of the work progress, the project was successfully implemented despite many difficulties.

Jacek Stankiewicz

President Elsta Sp. z o.o.The initial reluctance of the installation teams to use the AMAGE system disappeared after two weeks, and after two months we all knew that without Amage Installation Master we would not have avoided major organizational and financial problems in a project where almost 50% of the original cable list had changed during the implementation. , we had up to 400 employees on the construction site per day, and we laid over 80 km of cables per week.